Industry

这里是标题一h1占位文字

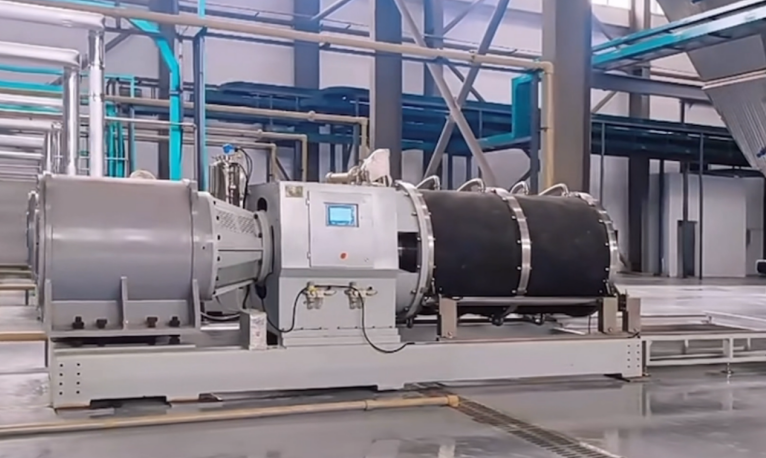

Permanent Magnet Direct Drive (PMDD) Motor Used in New Energy Industry

Case Study

| 10kV 630kW Permanent Magnet Direct-Drive Motor in Sand Mill Grinding Applications |  |

Project Background

One of top tier New Energy company partnered with Jasung to replace traditional gearbox-driven systems with high-voltage permanent magnet synchronous motors (PMSM) in their large-scale sand milling production lines. The goal: eliminate transmission losses, reduce downtime, and cut energy costs by 20%+ in precision grinding operations.

Why Permanent Magnet Direct-Drive?

• Energy Savings

20% lower power consumption vs. induction motor + gearbox systems.

Near-unity power factor (>0.95) reduces reactive power penalties.

• Zero Transmission Losses

Direct coupling to the mill shaft eliminates gears, couplings, and belts.

98% system efficiency (vs. 85–90% for conventional drives).

• Precision Control

±1 RPM stability via integrated vector control, critical for particle size consistency.

Instant torque response (<50ms) prevents material agglomeration.

• Maintenance-Free Operation

No lubrication or gear wear – 90% fewer mechanical failures reported.

50,000+ hour bearing life with predictive maintenance alerts.

High-Voltage Design: 10kV operation minimizes current losses in long cable runs.

Cooling System: Water cooling maintains <65°C winding temperature.

Onsite video

Related Industries

Tel: +86-400-686-9980

Address: No. 108, Changtang Road, Wujin District, Changzhou, Jiangsu, China