Industry

这里是标题一h1占位文字

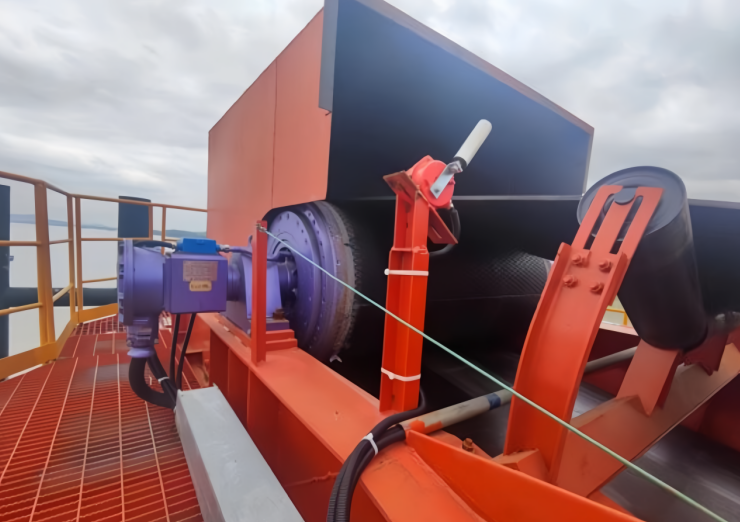

Permanent Magnet Direct Drive (PMDD) Pulley Used in Port Belt Conveyor

Project Overview

| Location | Lukanzhou, Chunjiang Town, Xinbei District, Changzhou, China |

| Coordinates | 119°58'E, 31°59'N |

| Distance | ~30km to downtown Changzhou, ~250km to Shanghai Wusongkou |

| Scope | Retrofit of 2 existing conveyors and addition of new conveying systems (including stackers, transfer stations, and bucket-wheel stacker/reclaimers) to connect the stockyard to Jiangjiang Wharf |

Conveyor System Specifications

| No. | Name | Length (m) | Belt Width (mm) | Speed (m/s) | Capacity (t/h) | Incline Angle (°) | Motor Power (kW) | Drive Type | Take-up Type | Status |

| 1 | D01-1 | 27.4 | 1400 | 2.5 | 1100 | 4.439 | 250 | PMDD Head Pulley | Screw Tail | Retrofit |

| 2 | D02-1 | 27.4 | 1400 | 2.5 | 1100 | 4.439 | 250 | PMDD Head D Pulley | Screw Tail | Retrofit |

| 3 | C01 | 216.7 | 1400 | 2.5 | 2500 | 8.301 | 355 | PMDD Head Pulley | Gravity | New |

| 4 | C03 | 28.638 | 1400 | 1.5 | 90 | 0 | 0 | PMDD Head Pulley | Screw | New |

| 5 | C05 | 274.746 | 1400 | 2.5 | 2500 | 5.015+7.038 | 315 | PMDD Head Pulley | Gravity | New |

| 6 | C07 (BC09B) | 343.662 | 1400 | 2.5 | 200×2 | 0 | 400 (dual drive) | PMDD Center Pulley | Hydraulic | New |

PMDD Pulley Motor Specifications

| Parameter | Specification |

| Model | STYB200-2.5-1000×1400(660) |

| Quantity | 2 units |

| Power | 200 kW |

| Belt Speed | 2.5 m/s |

| Rated Voltage | 660 V |

| Rated Current | 191 A |

| Rated Speed | 47 rpm |

| Protection Class | IP55 (Dust/water resistant) |

| Insulation Class | Class H (High-temperature resistant) |

| Cooling Method | Water-cooled (IC W37) |

Matching Variable Frequency Drive (VFD)

Model: BP250-660 (Dedicated for PMDD pulley motors)

Additional PMDD Pulley Motors in Operation

The following models have demonstrated equivalent performance in the same application:

• STYB355-2.5-1250×1400(660) – 1 unit (355 kW)

• STYB110-2.5-800×1400(660) – 2 units (110 kW each)

• STYB315-2.5-1250×1400(660) – 1 unit (315 kW)

• STYB90-2.5-800×1400(660) – 1 unit (90 kW)

Operational Performance

Since installation and commissioning, our company’s management has closely monitored the equipment’s performance, with dedicated technicians conducting on-site inspections. After extended operation, the following observations are summarized:

• Reliable Pulley Performance

Even during peak discharge periods, the belt conveyor restarts smoothly at low speed after stopping, preventing material blockages ("belt jams").

No instances of overcurrent or excessive temperature rise in the Pulley motor.

• Stable Load Operation

Under normal load, the Pulley’s operating current remains steady at 80–150 A, with coil temperature below 70°C, demonstrating excellent thermal management.

• Precision Control via Dedicated VFD

At rated frequency, the no-load current stabilizes at 5–10 A, confirming energy-efficient idling.

Master-slave synchronization accuracy: Current deviation ≤ 2 A; frequency deviation ≤ 0.1 Hz.

• Energy Savings

32% reduction in power consumption compared to traditional drive systems, validated by long-term current monitoring.

Onsite video

Summary & Evaluation

• Compact & Space-Saving Design

The PMDD Pulley’s integrated structure reduces footprint by 70% versus conventional drives (motor + gearbox), simplifying wharf construction and support requirements.

Eliminates oil leaks and noise pollution from gearboxes, enhancing environmental compliance.

• Superior Heavy-Duty Performance

Low-speed startup under full load ensures reliable bulk material handling, critical for stockyard operations.

Low no-load current minimizes energy waste and extends service life.

• Minimal Maintenance

Simplified mechanical design (fewer transmission components) slashes post-installation upkeep.

Related Industries