Blog

[Industry News]The development of permanent magnet motors and their applications in various fields

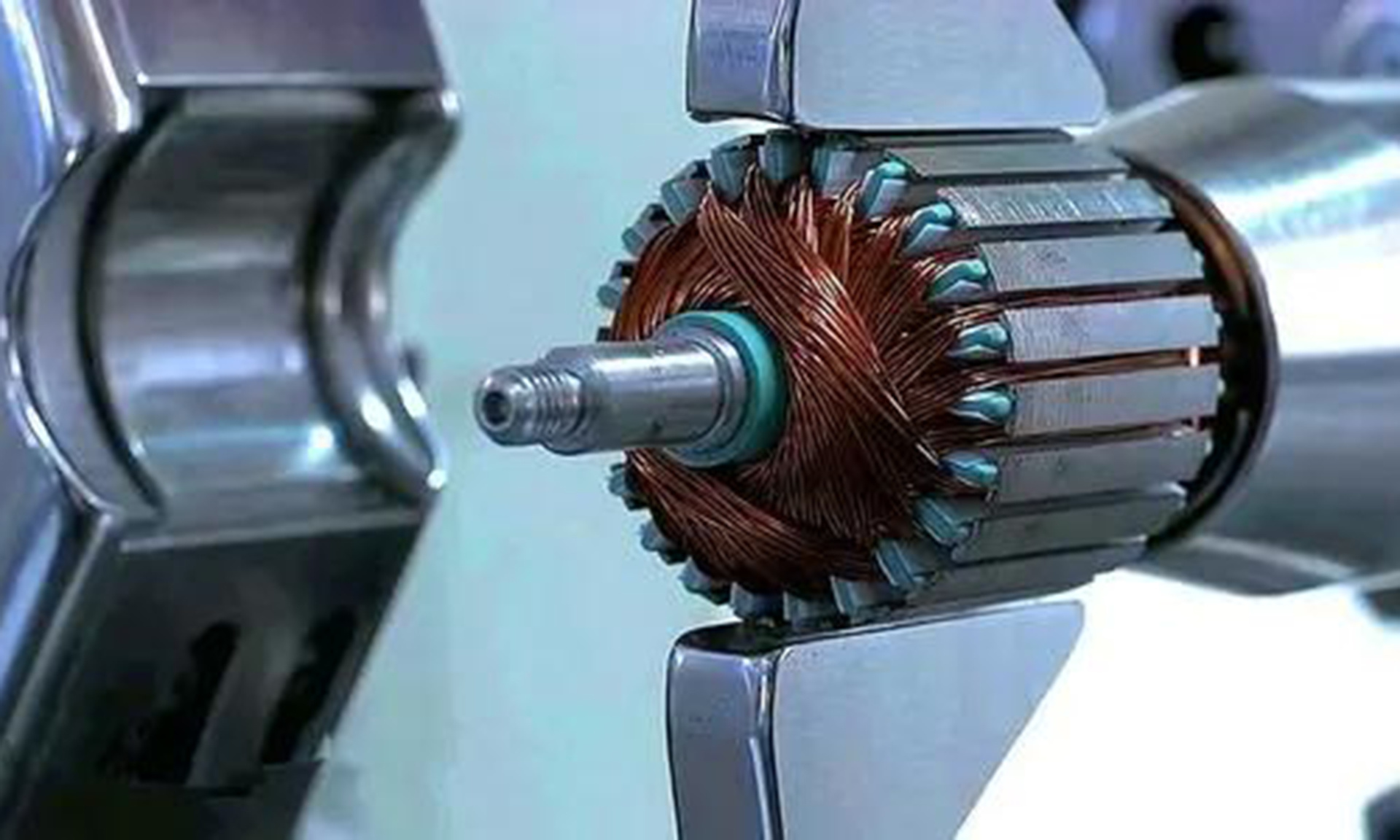

The permanent magnet motor uses permanent magnets to generate the motor's magnetic field. It does not require excitation coils or excitation currents. It has high efficiency and simple structure. It is a good energy-saving motor. With the advent of high-performance permanent magnet materials and the rapid development of control technology. The application of permanent magnet motors will become more extensive.

The development history of permanent magnet motors

The development of permanent magnet motors is closely related to the development of permanent magnet materials. my country is the first country in the world to discover the magnetic properties of permanent magnet materials and apply them to practice. More than two thousand years ago, my country made a compass using the magnetic properties of permanent magnet materials, which played a huge role in navigation, military and other fields. It has become one of the four great inventions in ancient my country.

The first motor in the world that appeared in the 1820s was a permanent magnet motor that generated an excitation magnetic field from a permanent magnet. But the permanent magnet material used at that time was natural magnetite (Fe3O4), which had a very low magnetic energy density. The motor made from it was huge and was soon replaced by an electric excitation motor.

With the rapid development of various motors and the invention of current magnetizers, people have conducted in-depth research on the mechanism, composition and manufacturing technology of permanent magnet materials, and successively discovered carbon steel and tungsten steel (the maximum magnetic energy product is about 2.7 kJ/m3). ), cobalt steel (maximum magnetic energy product is about 7.2 kJ/m3) and many other permanent magnet materials.

Especially the AlNiCo permanent magnets that appeared in the 1930s (maximum magnetic energy product can reach 85 kJ/m3) and the ferrite permanent magnets that appeared in the 1950s (maximum magnetic energy product can reach 40 kJ/m3), the magnetic properties are With great improvement, various micro and small motors have used permanent magnets for excitation. The power of permanent magnet motors is as small as a few milliwatts and as large as tens of kilowatts. They are widely used in military, industrial and agricultural production and daily life, and their output has increased sharply. Correspondingly, breakthroughs have been made in the design theory, calculation method, magnetization and manufacturing technology of permanent magnet motors during this period, and a set of analytical research methods represented by the permanent magnet working diagram graphical method have been formed.

However, the coercivity of AlNiCo permanent magnets is low (36~160 kA/m), and the remanence density of ferrite permanent magnets is not high (0.2~0.44 T), which limits their application range in motors. Until the 1960s and 1980s, rare earth cobalt permanent magnets and neodymium iron boron permanent magnets (both collectively referred to as rare earth permanent magnets) came out one after another, their high remanence density, high coercivity, high energy product and linear demagnetization curve Its excellent magnetic properties are particularly suitable for the manufacture of motors, so that the development of permanent magnet motors has entered a new historical period.

Features and applications of permanent magnet motors

Compared with traditional electric excitation motors, permanent magnet motors, especially rare earth permanent magnet motors, have a simple structure, reliable operation; small size, light weight; low loss, high efficiency; the shape and size of the motor can be flexible and diverse and other significant advantages . Therefore, the application range is extremely wide, covering almost all fields of aerospace, national defense, industrial and agricultural production and daily life. The main features of several typical permanent magnet motors and their main applications are introduced below.

Compared with traditional generators, the rare-earth permanent magnet generator permanent magnet synchronous generator does not require a slip ring and brush device, has a simple structure, and reduces the failure rate. The use of rare earth permanent magnets can also increase the air gap magnetic density, increase the motor speed to the best value, and improve the power-to-quality ratio. Almost all generators for modern aviation and aerospace use rare earth permanent magnet generators. Its typical products are the 150 kVA 14-pole rare earth cobalt permanent magnet synchronous generators with 12 000 r/min~21 000 r/min and 100 kVA 60 000 r/min manufactured by General Electric Company of the United States. The first rare earth permanent magnet motor developed in China is a 3 kW 20 000 r/min permanent magnet generator.

Permanent magnet generators are also used as auxiliary exciters for large turbo-generators. In the 1980s, my country successfully developed the 40 kVA~160 kVA rare earth permanent magnet auxiliary exciters with the largest capacity in the world at that time. After being equipped with 200 MW~600 MW steam turbine generators Greatly improve the reliability of power station operation.

At present, internal combustion engine driven small generators for independent power sources, permanent magnet generators for vehicles, and small permanent magnet wind generators directly driven by wind wheels are gradually being promoted.

The important role of permanent magnet motors in various application fields

1 Energy-saving rare earth permanent magnet motors are mainly used for consumption, such as rare earth permanent magnet synchronous motors for textile and chemical fiber industries, petroleum, mining, rare earth permanent magnet synchronous motors in coal mine transportation machinery, rare earth permanent magnet synchronous motors drive various pumps and fans.

2 Various rare earth permanent magnet motors are used by various types of vehicles (cars, motorcycles, trains), and rare earth permanent magnet motors are the largest market. According to statistics, about 70% of the rare earth permanent magnet motors used in vehicles. For luxury cars, there are more than 70 sets of motors for various applications. Since the requirements of various automobile motors are different, the choice of permanent magnet materials is different. Motor magnets are used in air conditioners, fans, and power windows. From the perspective of price, the advantages of ferrite will continue in the future. Sm-Co sintered magnets are still used for ignition coils, driving devices, and sensors. In addition, auto parts are also not negligible for electric vehicles, as an environmentally friendly (EV) and hybrid electric vehicle (HEV).

3 Rare earth permanent magnet motor AC servo system A set of electronic, high-performance, speed control system mechatronics machinery. The system is a self-controlled permanent magnet synchronous motor main body. The system is used for the development of CNC machine tools, flexible manufacturing technology; also used for electric vehicles, instead of traditional thermal power vehicles, free of vehicle emissions. Rare-earth permanent magnet motors are a kind of high-tech industry with promising development.

4 The new field is mainly for the support of the new low-power rare earth permanent magnet synchronous motor variable frequency speed control system for new air conditioners and refrigerators, and wireless electric gadgets used for various rare earth permanent magnet DC micro motors. The rare earth permanent magnet brushless DC motors are Instruments of different power. The demand for such motors is also great.

5 The rare earth permanent magnet material, which is advantageous in aerospace applications, makes it very suitable for aero-engine applications. Although there are some applications of rare earth permanent magnet motors in the air (such as generator voltage and short circuit protection, etc.), experts at home and abroad agree that rare earth permanent magnet motors are an important development direction for a new generation of aeroengines.

Cost issue

Ferrite permanent magnet motors, especially miniature permanent magnet DC motors, are widely used because of their simple structure and reduced quality, and their total cost is generally lower than that of electrically excited motors. As the current price of rare earth permanent magnets is still relatively expensive, the cost of rare earth permanent magnet motors is generally higher than that of electric excitation motors, which needs to be compensated by its high performance and savings in operating costs.

In some occasions, such as the voice coil motor of a computer disk drive, the performance of the neodymium iron boron permanent magnet is improved, the volume and mass are significantly reduced, and the total cost is reduced. In the design, it is necessary to make a decision based on the specific use occasions and requirements, after comparing the performance and price, and also to carry out the innovation and design optimization of the structure process to reduce the cost.

Related Blog