PRODUCT

CONTACT

-

400-686-9980

Mail:jiaxuan@jasung.cn

Add:No. 502, Changting Road, Wujin Economic Development Zone, Changzhou City, Jiangsu Province

Equipment online monitoring

Jiaxuan Electromechanical Guard. 360-degree protection

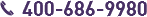

VCMTMGuardian industrial cloud intelligent equipment status management system is a collection of NB-lOT and other wireless wide-area Internet of things technology, artificial intelligence, cloud computing and other core technologies by Jiaxuan Intelligent Industrial Technology Co., Ltd., and the computer system automatically completes the online status of on-site equipment Monitoring, intelligent diagnosis and analysis.

Jiaxuan Electromechanical Guard is based on core technologies such as industrial Internet of Things technology, artificial intelligence, cloud computing and so on. The computer system automatically completes online monitoring, intelligent diagnosis and analysis of on-site equipment status;

Let you and the device no longer have "distance", real-time can "understand";

The equipment status can be "visualized, analyzed, and improved";

Provide enterprises with: determine the state of the equipment, predict the future development trend of the equipment state, formulate a predictive maintenance plan in advance, determine the time, content, method, and necessary technical and material support for the machine to be repaired.

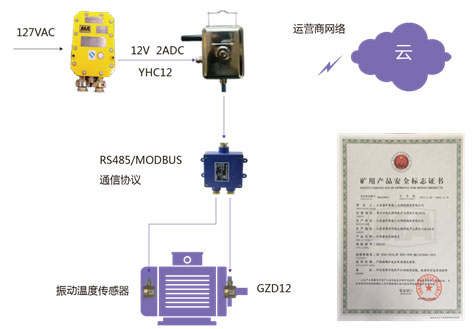

Electromechanical Guardian—Industrial Cloud Intelligent Diagnosis Model MA Complies with the national safety standards for mining products and is suitable for mobile GPRS network coverage (ground) scenarios.

一、Universal "Electromechanical Guard"

Monitoring method:

• Power supply; 7X24 hours monitoring

• Characteristic value, complete waveform acquisition

• Wireless data upload

Features:

• Status online monitoring

• Equipment fault diagnosis and prediction

• On-site alarm and control

Effect:

Effectively improve the quality of equipment maintenance and reduce the workload of equipment inspection

Industry:

Industries such as steel mills, power plants, mines, coal washing plants, etc.

Scenes:

Field reducer, blower, water pump, belt conveyor, hoist, crusher

Applications:

Should be coal washing plant belt conveyor, coal washing plant water pump, steel mill blower and steel mill oil pump, etc.

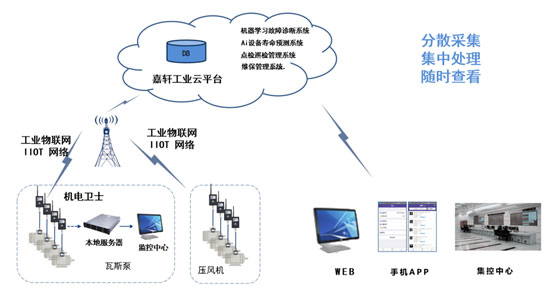

二、Ground Type "Electromechanical Guard" for Mine

Monitoring method:

• Power supply: 7X24 hours monitoring

• Characteristic value, complete waveform acquisition

• Wireless data upload

Features:

• Status online monitoring

• Equipment fault diagnosis and prediction

• On-site alarm and control

Effect: Improve equipment maintenance quality and reduce equipment inspection workload

Industry: Coal safety environment such as coal mines, coking plants, coal washing plants, etc.

Scenes: Reducer, gas pump, belt conveyor, main fan

Applications: Gas pump, main fan

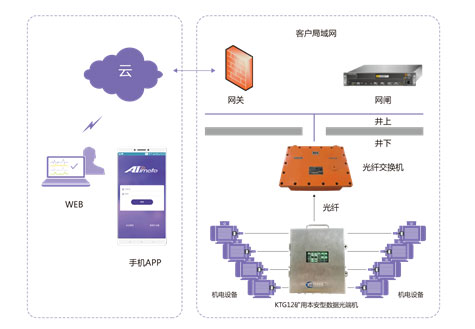

三、Mine cloud diagnostic "Electromechanical Guard"systems mannual

systems mannual:

Connect to the cloud server based on the underground data system of the electromechanical guard; it can be flexibly expanded

Must ensure an open and stable external network communication interface

Install external network communication equipment (gateway, gatekeeper, router, etc.), transmit data to the cloud in real time, and view data and alarms through mobile APP

Each set of external communication equipment supports at least 50 sets of downhole data subsystems (400 measuring points work at the same time)

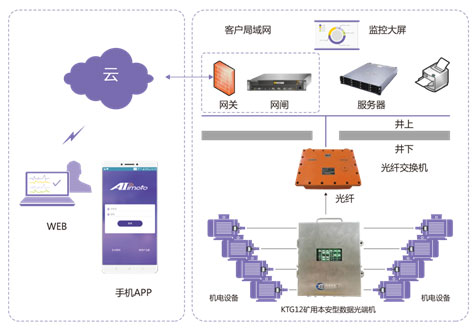

四、Mine server type "Electromechanical Guard"

systems mannual:

Install ground server subsystem; local data storage, local diagnosis

Each downhole data subsystem can be connected to 1~8 sensors; each additional 8 measuring points needs to add a downhole data subsystem

Each surface server subsystem can support 50 sets of downhole data subsystems (400 measuring points)

Optional external network communication equipment can be added to realize data upload to the cloud, and then data and alarms can be checked by mobile APP

External network communication equipment (gateway, gatekeeper, router, etc.), data cloud service, etc. are optional

Keywords:Permanent magnet direct drive drumIntelligent Industrial MotorBulk material conveying system

Recommended Products

Online Message

嘉轩智能

Contact Us

Mail:jiaxuan@jasung.cn

Address: No. 502, Changting Road, Wujin Economic Development Zone, Changzhou City, Jiangsu Province

Foloow Us

Jiangsu Jasung Intelligent Industrial Technology Co., Ltd. Website: www.300.cn Changzhou 苏ICP备17011957号