PRODUCT

CONTACT

-

400-686-9980

Mail:jiaxuan@jasung.cn

Add:No. 502, Changting Road, Wujin Economic Development Zone, Changzhou City, Jiangsu Province

MH821 CB BUFFERPROTECTION BAR

The unique buffering technology could control the acceleration to reduce the momentam and the reacting forceof belt so it could protect the belt.

PRODUCT PERFORMANCE

◇ The low-friction ultra-high molecular polyethylene surface minimizes the friction between the conveyor belt and the protection strip

◇ The wear resistance of ultra-high molecular weight polyethylene ensures the service life of the blanking protection strip itself

◇ The front and back ends of the ultra-high molecular weight polyethylene surface are all curved to ensure the smooth passage of the conveyor belt

◇ The buffer zone designed according to engineering mechanics effectively absorbs the impact of falling materials

◇ The integrated design of the falling material protection strip ensures compactness and firmness

◇ The surface contact between the falling material protection strip and the conveyor belt effectively prevents damage to the conveyor belt

◇ The uniform force of the conveyor belt during loading greatly reduces the maintenance and repair required

◇ Effectively eliminate material splashing and leakage caused by uneven force on the conveyor belt

◇ Reduce downtime to the shortest, thereby effectively improving production efficiency

TECHNICAL PARAMETERS

| Ambient temperature | -40℃~80℃ | Chemical fastness | PH2-12 |

| Relative humidity | 60%-70% | Tensile strength | >25N/mm2 |

| Elongation | >350% | lmpact strength | 10KJ/m2以上 |

| Extremely high abrasive resistance | 6.6 times of common alloy steel and27.3 times of stainless steel. | Long service life | For the low content of the unsaturated gene in the molecular chain,it could ensure the fatigue resistance is greater than 500000 times. |

APPLICATION

Used for bearing the impact force which generated by the dropping material in the tansferpoint of belt conveyor.

Used in the other parts of belt conveyor which come under the impact force of the material.3.Used for supporting the splitting part of belt conveyor.

Used in the other parts of belt conveyor which come under the impact force of the material.3.Used for supporting the splitting part of belt conveyor.

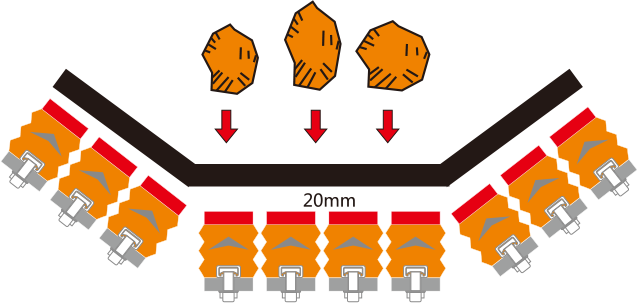

INSTALLATION DRAWING

Instllation diagram:By means of adjusting the rollers in front of and behind the buffering bar it could ensure there is a 20mm ditance between the beltand the buffering bar when there is no load on the belt.

| Number of buffering bar | Spacing (mm) | Roller width(mm) | ||||

| Belt width | Left | Center | Right | Two sides | Center | |

| 550 | 1 | 2 | 1 | 50 | 0 | 200 |

| 650 | 2 | 2 | 2 | 25 | 25 | 250 |

| 800 | 2 | 3 | 2 | 50 | 5 | 315 |

| 1.000 | 23 | 3 | 3 | 25 | 25 | 380 |

| 1.200 | 3 | 4 | 3 | 55 | 20 | 465 |

| 1.400 | 4 | 5 | 4 | 45 | 7 | 530 |

| 1.600 | 5 | 5 | 5 | 25 | 25 | 600 |

| 1.800 | 5 | 6 | 5 | 25 | 10 | 670 |

| 2.000 | 6 | 6 | 6 | 20 | 20 | 750 |

TYPE SELECTION

| Product code | Name | Width (mm) | Height (mm) | Length (mm) | UHMWPE thickness |

| 75390910 | Heavy | 75 | 100 | 1220 | 25 |

| 75390920 | Medium | 75 | 100 | 1220 | 12.5 |

| 75390500 | Medium | 75 | 100 | 1500 | 12.5 |

The buffering bar is only supplied for a complete setEvery buffering bar includes 4 M16× 40 fasteners.Also, the buffering bar length of 1400mmand 1600mm could be serienmaessig custom-made.

Keywords:Permanent magnet direct drive drumIntelligent Industrial MotorBulk material conveying system

Recommended Products

Online Message

嘉轩智能

Contact Us

Mail:jiaxuan@jasung.cn

Address: No. 502, Changting Road, Wujin Economic Development Zone, Changzhou City, Jiangsu Province

Foloow Us

Jiangsu Jasung Intelligent Industrial Technology Co., Ltd. Website: www.300.cn Changzhou 苏ICP备17011957号