Products

Energy-Saving Permanent Magnet Synchronous Motor for Water Pumps & Vacuum Systems (300kW-700kW)

◇ High efficiency (>95%), high power density, low maintenance. ◇ Requires a matched drive controller and cannot start directly from line frequency.

Classification:

Working Principle of Permanent Magnet Synchronous Motor (PMSM)

The Permanent Magnet Synchronous Motor (PMSM) converts electrical energy into mechanical energy through electromagnetic interaction. Its core working principle is as follows:

Magnetic Field Generation

◇ Stator: When three-phase AC current flows through the stator windings, it generates a rotating magnetic field (speed determined by the power supply frequency).

◇ Rotor: Equipped with permanent magnets (e.g., neodymium iron boron), creating a fixed magnetic field.

Synchronous Rotation

◇ The stator’s rotating magnetic field "pulls" the rotor’s permanent magnetic field, forcing the rotor to rotate at the same speed (synchronous speed) without slip.

Torque Generation

◇ The angle (load angle) between the stator’s magnetic field and the rotor’s permanent magnetic field produces electromagnetic torque, driving the load.

◇ By adjusting the current phase (vector control), torque output efficiency can be optimized.

Key Features

◇ High efficiency (>95%), high power density, low maintenance.

◇ Requires a matched drive controller and cannot start directly from line frequency.

| Product | Product Category | Voltage | Power Range | Product Application |

| Permanent Magnet Synchronous Motor 600-3000RPM |

Explosion-proof | 380/415V/460V | 11KW-315KW,355KW-710KW | Oil & gas extraction (drilling rigs, oil pumps, compressors) Refineries (reactor agitators, centrifugal pumps) Chemical plants (flammable liquid transfer, gas compression) Underground ventilation fans, conveyor belt drives Coal dust transport equipment, drainage pumps Alcohol extraction workshops, spray drying towers Flour/sugar powder conveying systems, edible oil pressing equipment |

| 660V | 11KW-315KW,355KW-710KW | |||

| 1140V | 11KW-315KW,355KW-1600KW | |||

| 3300V/4610V | 200KW-1600KW | |||

| 6000V | 200KW-1600KW | |||

| 10000V | 200KW-1600KW | |||

| Non-explosion proof | 380/415V/460V | 11KW-315KW,355KW-710KW | For textile/engineering vehicles/belt machine tightening/ air cooling island/flotation machine/separator/mixer/grinding machine/ball mill etc |

|

| 660V | 11KW-315KW,355KW-710KW | |||

| 1140V | 11KW-315KW,355KW-3000KW | |||

| 3300V/4610V | 200KW-3000KW | |||

| 6000V | 200KW-3000KW | |||

| 10000V | 200KW-3000KW |

Technical Specifications

Other voltages customizable, up to 10KV

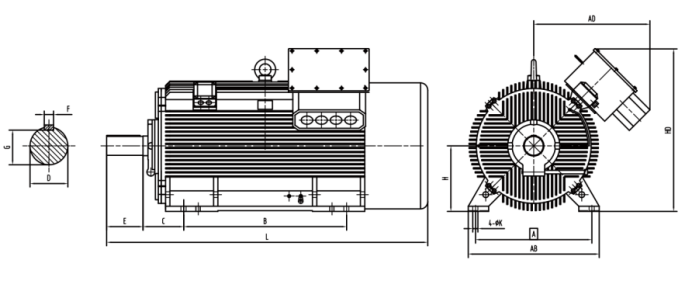

| Frame | Pole | Installation dimensions | Outline size | |||||||||||

| A | B | 0 | D | E | F | G | H | K | AB | AD | HD | L | ||

| 355 | 4~10 | 630 | 800 | 224 | 110 | 210 | 28 | 100 | 355 | 35 | 760 | 760 | 1130 | 1950 |

| 400 | 4-10 | 710 | 900 | 224 | 120 | 210 | 32 | 109 | 400 | 35 | 840 | 900 | 1260 | 2180 |

| 450 | 4~10 | 800 | 1000 | 250 | 130 | 210 | 32 | 119 | 450 | 42 | 990 | 940 | 1380 | 2250 |

| Model | Rated Power (kW) |

Rated Voltge A |

Rated Current A |

Syncvonous apeed (r/min) |

Raled Torque (N.m) |

Rated Emcency (%) |

Rated Power Fador |

Pull in torque mulipler |

Pul-out torque mutpler |

Locked-rotor torgue mutpller |

Locked-rotor current multipher |

| JXSS-355-4-355-380 | 355 | 380 | 580.4 | 1500 | 2259.9 | 96.8 | 0.96 | 12 | 1.6 | 17 | 9.5 |

| JKSS-400-4-355-380 | 400 | 380 | 654 | 1500 | 2546.4 | 96.8 | 0.96 | 1.2 | 1.6 | 17 | 9.5 |

| JKSS-450-4-355-380 | 450 | 380 | 735.8 | 1500 | 2854.7 | 96.8 | 0.96 | 12 | 1.6 | 17 | 9.5 |

| JKSS-500-4-400-380 | 500 | 380 | 817.5 | 1500 | 3183.0 | 96.8 | 0.96 | 1.2 | 1.6 | 1.7 | 9.5 |

| JXSS-560-4-400-380 | 560 | 660 | 527.2 | 1500 | 3565.0 | 96.8 | 0.96 | 1.2 | 1.6 | 1.7 | 9.5 |

| JXSS-630-4-400-380 | 630 | 660 | 593.1 | 1500 | 4010.6 | 968 | 0.96 | 12 | 1.6 | 1.7 | 9.5 |

| JXSS-710-4-450-380 | 710 | 660 | 668.4 | 1500 | 4519.9 | 968 | 0.96 | 12 | 1.6 | 1.7 | 9.5 |

| JXSS-800-4-450-380 | 800 | 660 | 753.1 | 1500 | 5092.8 | 968 | 0.96 | 12 | 1.6 | 1.7 | 9.5 |

| JXSS-900-4-450-380 | 900 | 660 | 847.2 | 1500 | 5729.4 | 968 | 0.96 | 1.2 | 1.6 | 1.7 | 9.5 |

| JXSS-280-6-355-380 | 280 | 380 | 459.7 | 1000 | 2673.7 | 96.4 | 0.96 | 1.2 | 1.6 | 19 | 9.5 |

| JXSS-315-6-355-380 | 315 | 380 | 517.2 | 1000 | 3007.9 | 96.4 | 0.96 | 1.2 | 1.6 | 19 | 95 |

| JXSS-355-6-355-380 | 355 | 380 | 582.8 | 1000 | 3389.9 | 96.4 | 0.96 | 12 | 1.6 | 19 | 9.5 |

| JXSS-400-6-400-380 | 400 | 380 | 656.7 | 1000 | 3819.6 | 96.4 | 0.96 | 12 | 1.6 | 19 | 9.5 |

| JXSS-450-6-400-380 | 450 | 380 | 738.8 | 1000 | 4297.1 | 96.4 | 0.96 | 12 | 1.6 | 19 | 9.5 |

| JXSS-500-6-400-380 | 500 | 380 | 820.9 | 1000 | 4774.5 | 96.4 | 0.96 | 12 | 1.6 | 1.9 | 9.5 |

| JXSS-560-6-450-380 | 560 | 660 | 529.4 | 1000 | 5347.4 | 96.4 | 0.96 | 1.2 | 1.6 | 1.9 | 9.5 |

| JX5S-630-6-450-380 | 630 | 660 | 595.5 | 1000 | 6015.9 | 96.4 | 0.96 | 1.2 | 1.6 | 19 | 9.5 |

| JXSS-710-6-450-380 | 710 | 660 | 671.1 | 1000 | 6779.8 | 96.4 | 0.96 | 1.2 | 1.6 | 19 | 9.5 |

| JXS5-220-8-355-380 | 220 | 380 | 363.5 | 750 | 2801.0 | 95.8 | 0.96 | 12 | 1.6 | 1.8 | 9.5 |

| JXSS-250-8-355-380 | 250 | 380 | 413 | 750 | 3183.0 | 95.8 | 0.96 | 12 | 1.6 | 1.8 | 9.5 |

| JXSS-280-8-355-380 | 280 | 380 | 462.6 | 750 | 3565.0 | 95.8 | 0.96 | 12 | 1.6 | 18 | 9.5 |

| JXSS-315-8-400-380 | 315 | 380 | 520.4 | 750 | 4010.6 | 95.8 | 0.96 | 12 | 1.6 | 18 | 9.5 |

Advantages of Permanent Magnet Synchronous Motor (PMSM)

High Efficiency & Energy Savings

◇ Achieves IE4/IE5 efficiency levels (up to 98%) due to zero rotor losses

◇ 15-30% lower energy consumption compared to induction motors

◇ Maintains high efficiency even at partial loads

Precision Performance

◇ Excellent speed stability (±0.1% speed regulation)

◇ Fast dynamic response with vector control capability

◇ Smooth torque production with minimal cogging

Low Maintenance & Long Life

◇ No brushes/slip rings (brushless design)

◇ Reduced wear with fewer moving parts

◇ Permanent magnets retain properties for decades

Smart Control Compatibility

◇ Seamless integration with modern drives and IoT systems

◇ Enables predictive maintenance through embedded sensors

◇ Adaptable to Industry 4.0 automation networks

Typical Pump Applications

| Centrifugal Pumps Applications: ◇ Municipal water supply ◇ Industrial circulating water systems ◇ HVAC systems (chilled/cooling water pumps) PMSM Advantages: ◇ IE5 ultra-high efficiency (>96%), significantly reducing long-term power consumption ◇ Pulsation-free flow, protecting pipeline systems ◇ Supports variable-frequency constant-pressure water supply, preventing water hammer effects Submersible Pumps Applications: ◇ Deep well water extraction ◇ Mine drainage ◇ Flood control and drainage PMSM Advantages: ◇ Fully sealed design (IP68), ensuring reliable underwater operation ◇ Corrosion-resistant materials (stainless steel/ceramic sleeves), suitable for acidic/alkaline water conditions ◇ Low-speed, high-flow design, reducing cavitation risks Multistage High-Pressure Pumps Applications: ◇ Boiler feed pumps ◇ Oil pipeline pressure boosting ◇ Seawater desalination PMSM Advantages: ◇ High-pressure output (up to 1000m head) ◇ Modular design, facilitating maintenance ◇ Precise pressure control (±0.1MPa) |

|

FAQ

Q: How does PMSM maintain performance in high-temperature environments?

Answer:Solutions:

◇ Uses high-temperature grade magnets (e.g., SH/UH grade NdFeB, rated for 180-200°C)

◇ Built-in temperature sensors + smart derating protection (auto-adjusts output if overheated)

Cooling system optimization:

◇ Low power: Forced air cooling (IC416)

◇ High power: Water jacket (IC6W7) or oil cooling

Q: How to mitigate harmonic interference in PMSMs?

Answer:Countermeasures:

◇ Drive side: Install input/output reactors

◇ Motor side: Sinusoidal winding design to reduce cogging harmonics

◇ System level: Deploy active power filters (APF) (THD <5%)

Q:Why are PMSMs ideal for servo applications?

Answer:Key advantages:

◇ Full torque at zero speed (can hold position without encoder, using magnetic sensing)

◇ 3-5x faster dynamic response vs. induction motors (acceleration up to 1000 rad/s²)

◇ Supports 23-bit high-resolution encoders (positioning accuracy ±0.01mm)

Q:How to diagnose PMSM demagnetization?

Answer:Methods:

1.Current analysis: >15% no-load current increase indicates possible demagnetization

2.Back-EMF test: Measure voltage drop during manual rotation (power off)

3.Thermal imaging: Localized hot spots on magnets

Q:Transportation & installation precautions for large PMSMs (>1MW)Answer:Critical steps:

◇ Lock rotor during transport (prevents magnetic attraction to metal debris)

◇ Mounting surface flatness ≤0.05mm/m²

◇ Mandatory magnetic pole identification before first startup (avoids drive initialization failure)

Permanent Magnet Synchronous Motors (PMSMs) are advanced electric motors that utilize permanent magnets embedded in the rotor to generate a constant magnetic field. Unlike traditional induction motors, PMSMs do not require rotor current, which reduces energy losses, increases efficiency, and improves overall performance. These motors are widely used in industrial automation, robotics, electric vehicles, renewable energy systems, aerospace, and precision machinery due to their high power density, reliability, and excellent dynamic response.

The basic structure of a PMSM includes a stator with three-phase windings connected to a power supply and a rotor containing high-strength permanent magnets, typically made from materials such as neodymium-iron-boron (NdFeB). When the stator windings are energized, a rotating magnetic field is created, which interacts with the rotor magnets to produce torque. The synchronous nature of the motor ensures that the rotor rotates at the same speed as the stator’s magnetic field, providing precise speed control and stable operation, which is crucial for applications requiring accuracy.

PMSMs are highly efficient because the rotor does not carry current, minimizing I²R losses and reducing heat generation. This results in lower energy consumption and better thermal management, making PMSMs ideal for applications like electric vehicles, wind turbines, and other high-demand systems. The motors provide high torque even at low speeds and exhibit excellent acceleration and deceleration performance, ensuring optimal dynamic control.

Another advantage of PMSMs is their high power density. They can deliver more power relative to their size and weight compared to conventional motors, allowing for compact and lightweight designs. The robust construction ensures long operational life, minimal maintenance, and consistent performance even under continuous or heavy-duty operation. Advanced manufacturing processes, including precise magnet embedding and optimized stator winding design, improve torque smoothness, efficiency, and overall performance.

PMSMs are controlled using advanced electronic drives and controllers, such as vector control (field-oriented control, FOC) or direct torque control (DTC). These methods enable precise regulation of speed, torque, and position, making PMSMs highly suitable for robotics, CNC machinery, aerospace actuators, and automated manufacturing systems. Encoders or resolvers are commonly used to provide real-time feedback for closed-loop control, ensuring precise and responsive operation.

Thermal management is critical in PMSM design. Effective cooling solutions, including forced air, liquid cooling, or heat sinks, are employed to prevent overheating and maintain optimal performance. Proper thermal management prolongs component life, maintains consistent torque and speed, and ensures reliability under varying loads.

PMSMs also operate quietly with low vibration, which is beneficial in medical devices, precision instruments, home appliances, and electric vehicles. Smooth torque output reduces mechanical noise, while low vibration minimizes wear on connected components, improving overall system longevity.

These motors are versatile and adaptable to a wide range of power ratings, voltages, and operating conditions. They can be designed for low-voltage applications like small robotic drives or high-power systems such as electric trains, wind turbines, and marine propulsion. Rotor configurations, magnet types, winding arrangements, and cooling systems can be customized for specific requirements.

Overall, Permanent Magnet Synchronous Motors combine high efficiency, precise control, high torque density, low noise, and long service life, making them ideal for industrial automation, robotics, electric mobility, renewable energy, aerospace, and other high-performance applications. Their advanced design, robust construction, and flexible control options make them a cornerstone technology for modern electric motor solutions.

Keyword:

High Efficiency & Energy Savings

Precision Performance

Low Maintenance & Long Life

Smart Control Compatibility

Permanent Magnet Servo Motor

Find Your Products

Keywords:Permanent Magnet Direct Drive Pulley | Permanent Magnet Synchronous Motor | Permanent Magnet Direct Drive Motor

Related Products

Online Message

Please leave your email, our professional person will contact you asap!